Why Calcium Carbonate Powder is essential for Plastic Industry

Beyond cost, CaCO₃ improves the quality of plastic products. It enhances surface smoothness, increases gloss and opacity, and improves strength and stiffness when used correctly.

Here are some key benefits of using CaCO₃ in plastic manufacturing:

✔ Provides a smoother surface (especially with finer particles)

✔ Reduces shrinkage and improves dimensional stability

✔ Remains thermally stable during processing

✔ Enhances impact resistance at the right levels (8 phr)

✔ Improves flowability and processability (8 phr)

✔ Increases hardness and compressive strength

CaCO₃ in the Edgebanding Industry

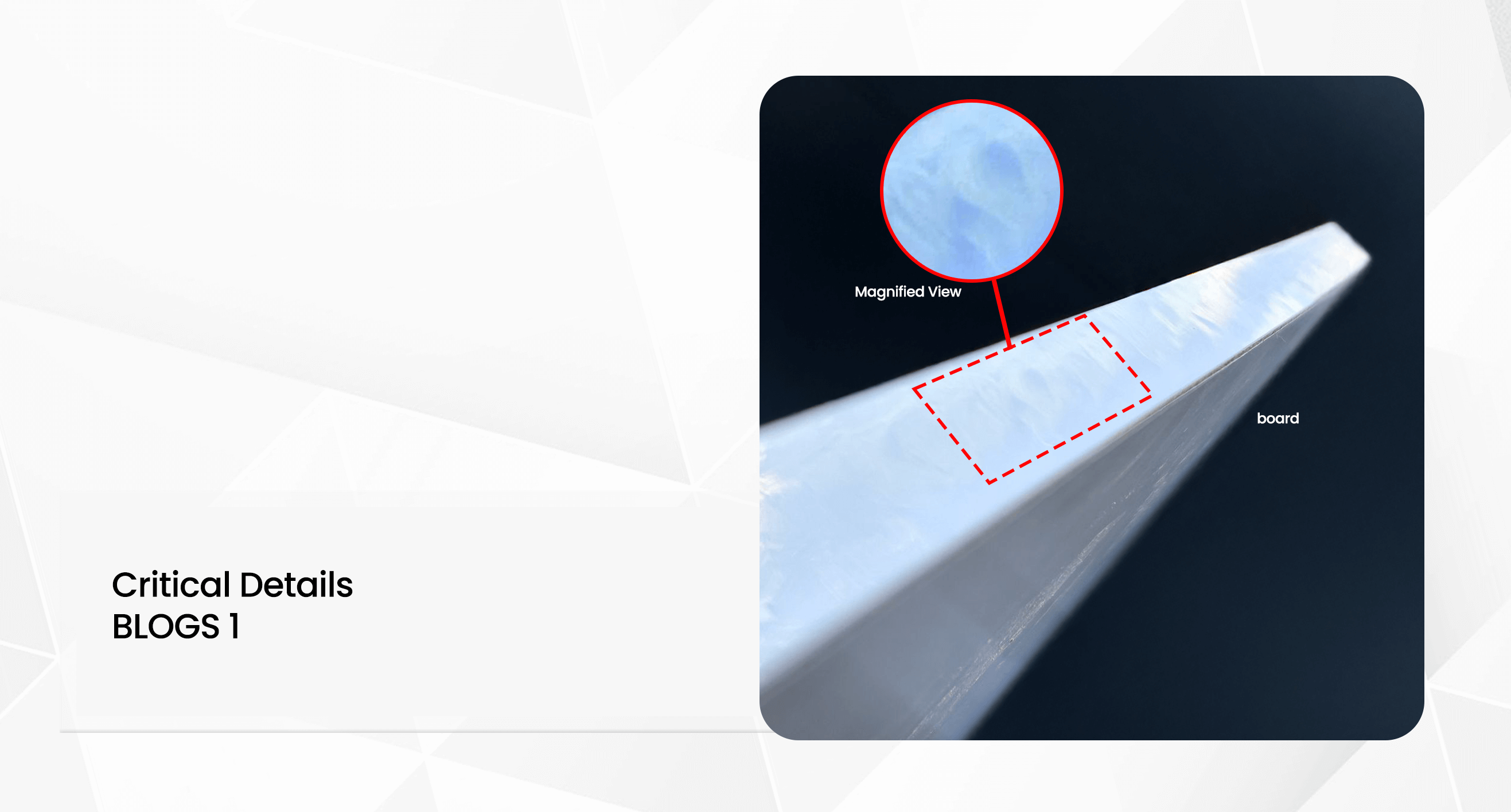

One challenge in edgebanding—especially with thinner materials—is the “telegraphing effect,” where surface imperfections from the underlying board become visible. Using CaCO₃ at optimal levels helps minimize these traces, resulting in a smoother finish.

While factors like chipboard quality and processing conditions also play a role, the key takeaway is that CaCO₃ is not just about cost savings. It enhances the performance and overall quality of edgebanding, leading to a better final product.